Ubudage Ikoranabuhanga rya Plastike PE PP Imashini isya

Ibisobanuro

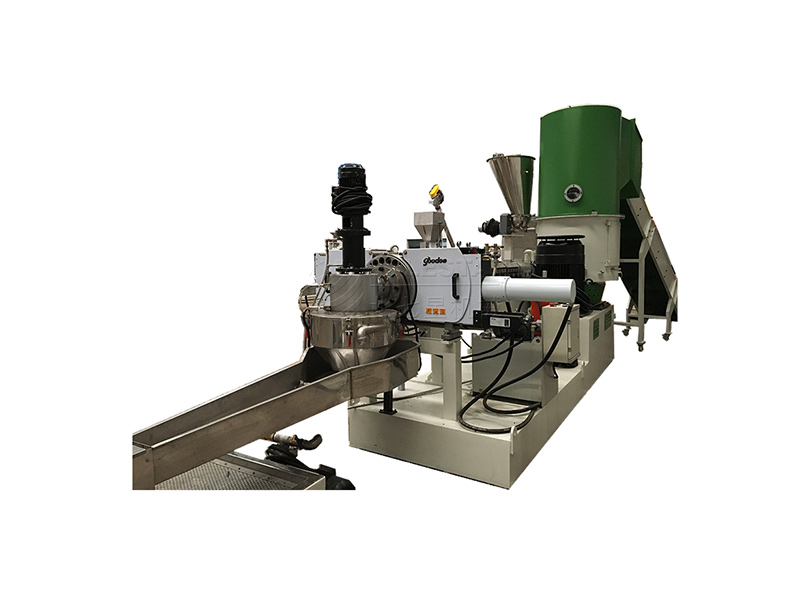

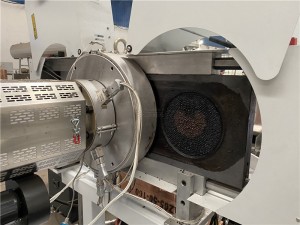

Imashini ya POLESTAR ya pelletizer / Plastike Granulators itanga ubushyuhe bumwe hamwe na homogenisation nibyiza kubyara pelletike muburyo bwo gutunganya. Imashini ya pelletizer ya plastike iraboneka murimwe (imashini imwe gusa yo gukuramo) hamwe no gutondekanya ibyiciro bibiri (imashini imwe nyamukuru yo gusohora hamwe na mashini ntoya ya kabiri yo gukuramo). Birasabwa ko ukoresha ibyiciro bibiri murwego rwo gutunganya ibintu kubera kwanduza ibikoresho bya plastiki. Hariho kandi uburyo butandukanye bwa tekinoroji ya granule pelletizing iboneka nka hydraulic ifashwa na ecran ya ecran hamwe na ecran ya piston ebyiri kugirango uhindure neza ko ntakabuza mugihe cyo guhindura ecran. Agasanduku k'ibikoresho byizewe bigenda byicecekeye kuvanga no kwimura plastiki yashongeshejwe muri barriel. Imashini ikozwe mubyuma byakozwe neza birinda kwangirika no kwangirika. Sisitemu yo kugenzura ubushyuhe bwa PID hamwe na sisitemu yo gukonjesha ikirere ikomeza ubushyuhe bwakazi. "Hot Cut" amazi-impeta ipfa guhura na pelletizing kandi "Cold Cut" uburyo bwa pelletizing burahari bitewe nibyo ukunda.

Gusaba

Ibikoresho bibisi: PE, PP Filime namashashi

Imashini ya plasitike ya plastike / imashini ya pelletizike / imashini ya pelletizer ya pulasitike hamwe na agglomerator irashobora gukoreshwa muri firime ya PE / PP cyangwa imifuka iboheye ya PP hamwe na parabolike pellet yongeye gukoreshwa, ibikoresho bizahagarikwa cyane hamwe na agglomeration bizoroha gutabwa kugirango bisohoke, zishobora kugera kubushobozi ntarengwa 100-100kg / isaha (biterwa nibisabwa nabakiriya)

Inyungu zo Kurushanwa

1. Urwego rwo hejuru rwihuta, gerageza neza kugabanya ikiguzi cyawe kumurimo kandi urebe ubushobozi bwo gutunganya cyane.

2. Sisitemu yo kugenzura neza (PLC ihuriweho & itandukanijwe igenzura kuri buri mashini) hamwe na Touch ecran ya panne, byoroshye gukora, gukurikirana no guhagarara byihutirwa.

3. Ibice byose bihura nibikoresho bya pulasitike namazi bikozwe mubyuma byo mu rwego rwo hejuru 304; Menya neza ko hatabaho umwanda wa kabiri kuri flake.

4. Umuhuza wa Siemens, umugenzuzi wubushyuhe bwa RKC

Ibyingenzi

1. Byikora cyane, kugenzura-gukoresha-kugenzura, gukora neza, kurengera ibidukikije no kuzigama ingufu;

2.

3. Multi-sitasiyo ya ecran ihinduranya na ecran ya ecran ihindura igishushanyo gishobora kugabanya imirimo yintoki no kunoza imikorere;

4. Icyiciro kimwe kandi kabiri, sisitemu nyinshi-zungurura kandi zungurura byemeza ubuziranenge nibicuruzwa;

5. Birakwiriye gutunganya ibikoresho bitandukanye, birashobora kandi gushushanya imashini kubintu bimwe cyangwa ibikoresho bitandukanye, bishobora kugabanya igiciro cyishoramari ryabakiriya.

Amakuru ya tekiniki

Icyiciro kimwe agglomeration granulation umurongo

| Icyitegererezo | 70 | 100 | 120 | 150 | 180 |

| Ibisohoka (kg / h) | 70-120 | 200-250 | 300-400 | 500-600 | 700-850 |

| Gukoresha ingufu (kWt / kg) | 700-850 | ||||

| Imbaraga nyamukuru (kW) | 37 | 90 | 110 | 132 | 185 |

| Imbaraga za Agglomerator (kW) | 30 | 55 | 75 | 110 | 132 |

| Kuramo diameter yo hanze (L / D) | 70 (33: 1) | 100 (30-35: 1) | 100 (30-35: 1) | 100 (30-35: 1) | 180 (30-32: 1) |

| Umwuka | Ihitamo | ||||

| Guhindura ecran | Iboneza bisanzwe | ||||

| Amazi-impeta | Ihitamo | ||||

| Ubukonje bukonje | Ihitamo | ||||

| Guhindura amazi | Ihitamo | ||||

Icyiciro cya kabiri agglomeration granulation umurongo

| Icyitegererezo | 70 + 90 | 100 + 120 | 120 + 150 | 150 + 180 | 180 + 200 |

| Ibisohoka (kg / h) | 110-180 | 200-300 | 300-450 | 500-650 | 700-850 |

| Gukoresha ingufu (kWt / kg) | 0.2-0.35 | ||||

| Imbaraga nyamukuru (kW) | 30 + 22 | 75 + 37 | 90 + 45 | 110 + 55 | 160 + 75 |

| Imbaraga za Agglomerator (kW) | 30 | 55 | 75 | 110 | 132 |

| Kuramo diameter yo hanze (L / D) | 70 (25 + 12: 1) | 100 (25 + 12: 1) | 120 (25 + 12: 1) | 150 (25 + 12: 1) | 180 (25 + 12: 1) |

| Umwuka | Ihitamo | ||||

| Guhindura ecran | Ibice 2 byimiterere isanzwe | ||||

| Amazi-impeta | Ihitamo | ||||

| Ubukonje bukonje | Ihitamo | ||||

| Guhindura amazi | Ihitamo | ||||

Ibyiciro byibicuruzwa

Urashaka Kongera Ijuru Mubishushanyo byawe?

Twandikire uyumunsi kugirango tujye inama.